Disposable gloves buying guide

Disposable Gloves

Disposable gloves are, under EU Health and Safety rules, officially an article of Personal Protective Equipment (PPE)and as such there is a duty on both the Management and users of gloves to carry out due diligence to ensure

the safety of the glove user.”

The enclosed information is provided to help you assess and determine what type of glove and

glove material would best suit your requirements.

Within this guide we have not attempted to determine which glove you should choose as there are

too many variables to be considered which means that each department will need to assess the

environment in which they work, the procedures being carried out and the materials to be used and

tested.

Disposable Gloves Types

General Purpose Gloves:Usually made from a form of plastic.

Loose fitting.

Ambidextrous - fit either hand.

Ideal in situations where a user is just wanting to stop hands from getting soiled (dirty).

Medical Examination Gloves:

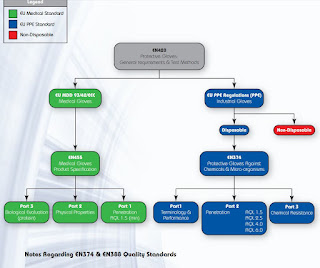

In Europe, examination gloves are manufactured to either EU PPE Standards or European Medical

Devices directive product standards.

Ambidextrous - fit either hand.

Fit the hand for maximum comfort security and sensitivity.

Can have a beaded cuff to help as an aid to donning and removing and also as a extra barrier security at

the wrist.

Available either powdered or powder free.

Available either ‘Sterile’ or ‘Non-Sterile’.

Procedural/Surgical/Surgeons:

Are a high quality product giving maximum security and fit.

Are hand specific - fit either left or right hand, are sized in half sizes from 5.0 to 9.5 and are usually

packed in pairs if sterile and boxes of gloves split left and right if non-sterile.

Note: All surgical/surgeons gloves are sterile.

Are the best at providing protection but are also the most expensive disposable gloves produced.

Are used for specialist procedures where maximum barrier protection and/or high levels of dexterity are

required.

Disposable Glove Risk Assessment

Risk of Procedure/Task Glove Material

Please Note:

1) Double Donning: Extra protection can be gained through the technique of double donning two disposable

gloves, where one glove is worn over another.

2) In using gloves, the use of non-disposable gloves should not be ruled out where risk is considered too

great for disposable gloves to be worn. In such cases, a loss of sensitivity and dexterity will occur.

Glove Materials Explained

Disposable gloves are made from a variety of different materials, all designed to fulfill a specific purpose

or purposes:

Co-Polymer (Plastic):

Advantages: They are cheap in price.

Fine for simple protection to keep hands clean.

Disadvantages: Offer little practical protection.

Very loose fitting and very smooth - makes handling

implements and carrying out tasks/procedures difficult.

Latex - Natural Rubber Latex (NRL):

Advantages: Effective barrier against most substances including

blood-borne pathogens.

The material is very thin allowing a high degree of

sensitivity.

The material is very strong and flexible.

The material’s molecular structure reduces the incidence

of pinholing or tearing when carrying out procedures/

tasks.

As the material comes from a natural renewable source

(rubber trees) it is ‘environmentally friendly’.

The material is cost effective.

Disadvantages: Residual soluble proteins in NRL can cause allergic

reactions in some glove users.

As a natural material NRL is not generally a good

barrier against chemicals.

Nitrile:

Advantages: Nitrile contains no residual protein and is a good alternative to

latex for glove wearers who are allergic to the soluble proteins

in latex.

An effective barrier against most substances including blood-borne

pathogens.

Is in general a better barrier against chemicals than NRL.

Disadvantages: It is not as flexible as latex, which can cause hand fatigue in glove

users who need to wear glove for long periods of time.

It is more expensive than latex but is still a cost effective barrier

material.

Vinyl:

Advantages: A cost-effective alternative to latex for glove wearers

who are allergic to soluble proteins or residual chemicals

in NRL gloves (low risk procedures only).

Disadvantages: Not a good barrier material against blood-borne pathogens

or chemicals.

Vinyl is more susceptible to pin holing then either latex or Nitrile.

Vinyl material is more ‘friable’ and can degenerate whilst being

worn when in contact with rough surfaces on instruments or items

being handled in the procedure or task.

Vinyl material can cause hand fatigue when worn for long periods

of time.

Low Risk - Where disposable gloves

are worn to keep hands clean or

reduce contact between the wearer

and item(s) handled.

Co-Polymer

Vinyl

Synthetic

Latex

Industrial PPE - “minimal risk”

or

EU EN455 medical standard.

Medium Risk - Where gloves are

being worn as task is deemed to

pose a medium risk i.e. staining

to the hand, minor chemical burns,

allergic reactions or cross contamination

between user and test subject.

Vinyl

Latex

Nitrile

Industrial PPE - “Class I”

or

EU EN455 medical standard watertight test value <AQL 1.5.

High Risk - Where gloves are worn

as the potential of serious health

issues through exposure to biohazard or chemicals are likely.

Latex

Nitrile

Specialist i.e Neoprene

Industrial PPE - “Class III”

or

EU EN455 medical standard

watertight test value <AQL 0.65

with high force at break value of >9 Newtons.

Glove Users Well Being

Gloves, correctly used, can provide the ideal protection against a wide range of potentially hazardous

substances and are an essential part of the PPE requirments of many institutions and businesses.

It is essential however, that the glove user takes the correct precautions both before and after the use

of gloves to ensure damge to the skin through prolonged use of gloves is prevented.

To ensure the well-being of the glove user, it is important to consider the following:

Pre-Donning Procedure:

Wash your hands - are there adequate hand washing facilities available?

Hand Lotions/Barrier Creams to protect the skin - Ensure any hand lotions/barrier creams

do not contain Coconut Oil, Jojoba, Lanolin, Palm Oil, Vasaline/Petroleum Jelly or any other

petroleum based product as these can damage the barrier properties of certain gloves.

Post-Donning Procedure:

Are there adequate glove disposal facilities available?

Are there adequate hand washing facilities available?

Does the glove user require post use hand creams or lotions?

Glove Storage and Barrier Protection

Even the best gloves can fail to perform correctly if you do not adhere to good user practice!

You should store disposable gloves away from direct sunlight and excessive heat. Never place gloves

on a window ledge or on a shelf above a radiator. If you are storing gloves on racking, consider the

temperature at ceiling height. Never store gloves at temperatures exceeding 40oC.

Glove boxes should not be left open in direct sunlight or near flourescent light sources as this will

accellerate the ageing process.

You should not wear hand creams or lotions containing any of the following materials or the barrier

integrity may be affected: Coconut Oil, Jojoba, Lanolin, Palm Oil, Vaseline/Petrolium Jelly or any other

petrolium based product.

Note: Water or glycerine based lotions or creams will not compromise the glove barrier.

You should not wear rings or jewellery with projections whilst wearing disposable gloves as such

items can puncture the glove barrier.

Sharp or long fingernails can puncture the glove barrier, check that your fingernails are rounded and

smooth before donning a glove.

disposable nitrile exam gloves

ReplyDelete